Printmaking as Studio Art

Printmaking Presses are heavy and expensive pieces of equipment. They are useful for making larger, unified editions for commercial purposes, but presses are not essential for individual artists wishing to make one-off or small edition prints in their personal studio spaces. Famous Japanese artists such as Katsushika Hokusai essentially printed all their masterpieces by hand using simple tools and techniques.

Since the advent of water based inks for intaglio etching in the late 1990s (for instance by printing with the Akua or Cranfield Caligo waterbased intaglio inks) it has become possible to print professional intaglio prints with lowered pressure on paper that is less damp than in the traditional, oil based process. And cleaning up is done using soap and water, not harsh solvents or spirits. Any of the hand tools shown below would be sufficient to give enough pressure for a good print, especially if multiple passes are used to build the impression.

Hand printing provides new creative opportunities during printing, — and progress can be checked in mid-printing. Light variations in each impression from the same plate or set of plates would be something to be embraced and appreciated, not rejected — as in Hokusai prints which were hand printed with a bamboo baren and often also painted on with brushes. Even some of the great Western Printmakers worked very freely with printed marks, with or without a press, for instance William Blake who made all his prints by hand, and with many manual additions, and not in the highly mechanized manner of the editioned or mass produced print.

a replica of Rembrandt’s solid wood etching press, Rembrandt House, Amsterdam; the top roller is driven which gives better results than lower roller drive

Any type of etching press has creative limitations due to the size, bed size, weight, footprint, and cost of the equipment, but gives consistent, predictable and quick results. Most commercial intaglio presses these days cost thousands of dollars, but bargains can be found on Ebay for both new and second hand models.

Roller Width x Pressure Relationship

Intaglio Etching presses require more pressure than other types of printing presses, to allow for stiff ink to transfer from lowered, incised areas of the plate. The wider the press rollers are, the lower the actual transferred pressure to the print will be. Large press designs involve expensive and heavy engineering — and heavy machine parts and rollers — to provide sufficient pressure for large prints. In a new concept solid print rollers can be just a few inches wide — giving maximum pressure — while being operated in multiple passes, building layers of ink, layer by layer, pass by pass, like an inkjet printer (e.g. The Wheelan press). This process is easily done by hand, and works even better with heavier handheld rollers. Several such models will be introduced lower down in this page.

Hand printing may be a somewhat slower process, requires multiple passes but setting up is easy and space saving, there are added creative possibilities, and prints can potentially be any size.

William Blake, The Marriage of Heaven and Hell, Plate 3

“Blake described his technique as “fresco.” It appears to be a form of monotype: using oil and tempera paints mixed with chalks, Blake painted the design onto a flat surface (a copperplate or piece of millboard), from which he pulled the prints simply by pressing a sheet of paper against the damp paint.”

Printmaking by Hand

Using the right inks and tools, today any of the key Fine Art printmaking methods can be practiced as a manual, hand-operated process in an artist’s studio, with professional results, and without the use of complex machines or presses:

Silkscreen | Intaglio | Drypoint | Monoprint | Intaglio Type and Solarplate | Aquatint | Collagraph | Relief | Polyester Plate Lithography | Kitchen Litho

Spoon Printing Demo: Serhat Tanyolacar; Florida

The Spoon Rubbing Technique

Throughout the 20th century artists frequently used a wooden cooking spoon as their printing tool of choice. With some patience even some very large scale prints (6ft x 4ft or larger) have been made in this manner. Often the print is made directly on top of the inked plate or block. Place a protective sheet of plastic or card on top during rubbing the print. Drypoint artists often use a metal spoon for rubbing, as it provides greater point pressure than a wider object.

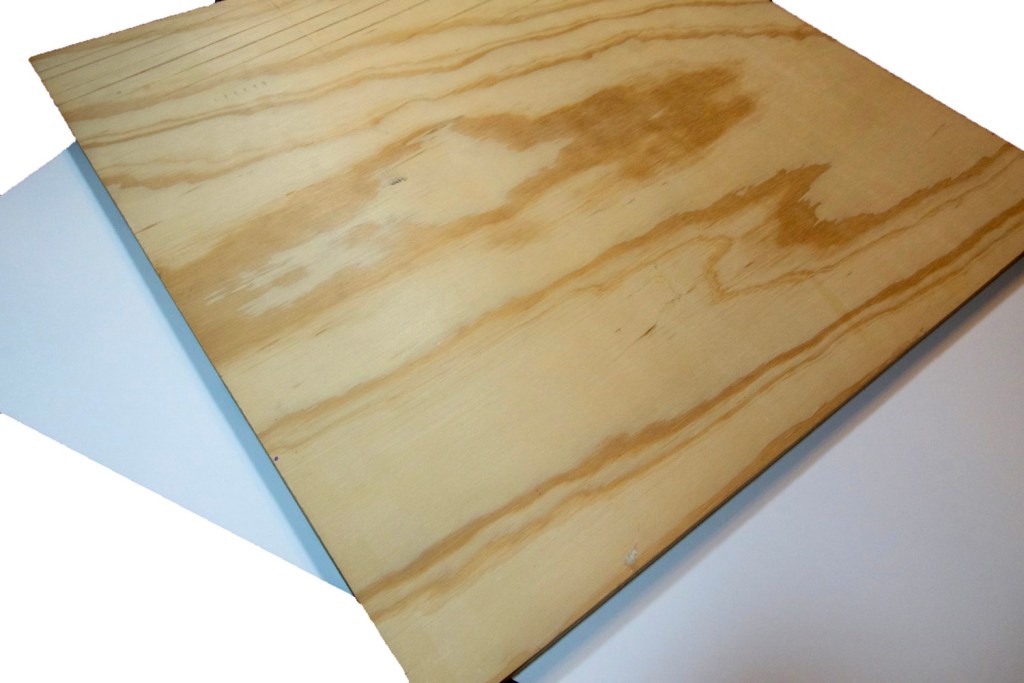

The Press Bed

Use a one inch sheet of plywood mounted on a stable surface, or on the floor, as your press bed; use materials such as soft felt blanket, foam blanket, or vinyl interfacing fabric as press cushions for intaglio projects, as in an etching press.

Akua Pin Press

Mainly designed for monoprinting, this press can also print intaglio prints if a softer ink is used; pressure will be a little lower than in spoon printing , where a direct point and rotary action mimics the pressures an etching press provides

Rolling Pins

A selection of different rolling pins. (left: a Walnutwood French Rolling pin that is tapered).

Hayley Thompson‘s rolling pin press

Printing with Massage Rollers

use a printing action that mimics plate wiping or paper blotting; the glove type device works best with one glove-press on each hand, working simultaneously with both hands across the plate surface to create the impression. (same as in Keith Howard’s Intaglio Type two handed plate wiping).

Roofing Rollers

Metal Roofing Rollers make a useful hand-held printing press. Due to the heavy weight these can provide a lot of pressure for intaglio work. In construction these inexpensive machines are used to press down and level metal sheeting on flat roofs. The devices come with a single roller or multiple rollers and weigh between 30lb and 100lb, which is much heavier than most regular printmaking rollers or pins. The device on the left has a strong handle which makes it ideal for printing, as it allows for two handed operation.

Product sample: Primelinetools.com

Asian Baren Printing

Relief Printing with a Spoon

Plexiglass Drypoint with Courtney Donahue